why we used

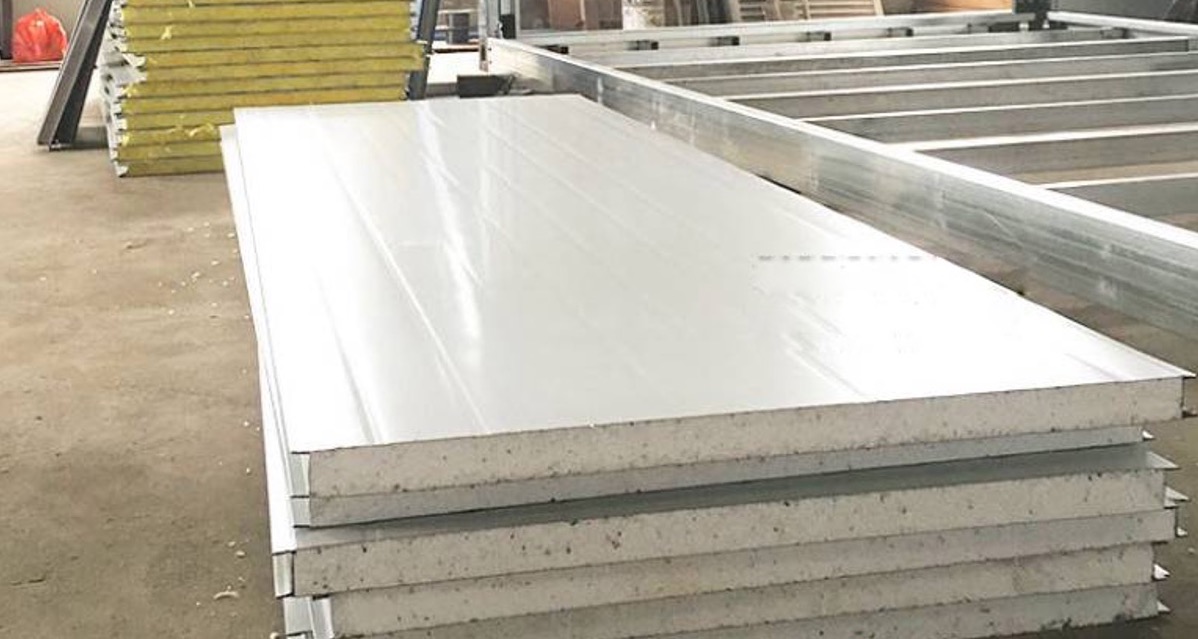

We use Insulated Metal Panels (IMPs) because they offer a smart, efficient, and durable solution for modern building construction — combining insulation, structure, and aesthetics in one product.

We use Insulated Metal Panels (IMPs) because they offer a smart, efficient, and durable solution for modern building construction — combining insulation, structure, and aesthetics in one product.

Here’s a detailed breakdown:

IMPs have built-in insulation, providing excellent thermal resistance (high R-value).

They reduce heating and cooling costs, maintaining stable indoor temperatures.

Ideal for energy-efficient and green building designs (LEED, sustainable projects).

Panels are prefabricated and ready to install, minimizing labor time.

They serve as both the insulation and exterior finish, so fewer materials and steps are needed.

This results in shorter construction schedules and lower installation costs.

Designed with interlocking joints that create airtight and watertight seals.

Prevents water infiltration, air leakage, and condensation issues.

Ensures long-lasting building envelope performance.

Many panels are made with fire-rated cores (such as PIR or mineral wool).

Provides enhanced fire protection for industrial and commercial buildings.

The metal skins (usually steel or aluminum) make the panels strong, rigid, and impact-resistant.

Withstand harsh environments — ideal for industrial, cold storage, and exterior facades.

Corrosion-resistant coatings extend lifespan even in coastal or humid climates.

Available in various colors, textures, and profiles to match design requirements.

Used to create modern, sleek building appearances without extra cladding.

Many panels use recyclable materials and environmentally friendly foam cores.

Reduce long-term energy use and carbon footprint.